Page Updated

9/11/2002

Selected Slides

Memory Pages

Bee Line

Michigan Div.

Train Orders

Hand Signals

NYC Power

NYC Mechanical

Drawings

Columbus Div.

Delco Tower

DOW Tower

Elwood

EA&L RR

Indian Creek

Circus Trains

RB&BB Train

Contact the

Webmaster:

Roger Hensley

|

Railroads of Madison County Maurice Lewman Memories |

Working the AirSeptember 11, 2002 We have been previously discussing the firing of steam engines and the feel of power coming from the drivers through the frame into the cab. Now, we will show how the speed is controlled and stops made by using the air brake. This takes place on the Michigan Division between Elkhart Indiana and Jeffersonville Indiana. The steam engine experience was on the B&O RR. between North Vernon and WS Tower. The Big Four leased 53 miles of B&O track for an entrance to Louisville Kentucky. The rest of the story took place at Wabash Indiana. The hills out of Wabash were the steepest on the Big Four except between Evansville and Terre Haute. The only way to have enough power was to think tonnage. When you hired on the NYC in 1950, it meant steam engines, coal dust, cold bunk rooms and 16 hour days. These were the things physical but you did get to watch the throttle and air artists at work. Imagine firing an H-10 2-8-2 Mike at 60 mph and going to head in the siding about a mile ahead. You start getting ready for the stop by cutting back on your firing and crack the blower. You set back and watch the engineer, Walter, work his magic. Walter reduces throttle from wide open to about 3/4 and makes a 5-7 pound brake reduction. With his eye on the switch judging the distance and speed, as he gets closer he adjusts the throttle and makes another small reduction of the brakes. Still watching and judging, just at the proper time, Walter closes the throttle, makes a full brake reduction and stops about 40 feet from the switch. You could say he was lucky or sure he did it that time, but it was skill, a skill learned and practiced over the years. I have watched Walter and other engineers make this kind of stop day after day at different locations along the railroad.

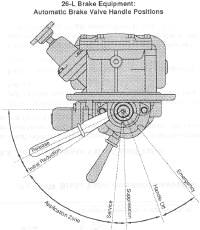

Today's engineer might ask, why not use the dynamic brake? Until the last few years, at least on the NYC and Conrail, the dynamic brake either didn't work or the tonnage was too heavy. Because of this you naturally learned to use the air brakes. The NYC never used the holding position or had a maintaining feature on their automatic brake valve. Until the 26 brake valve, engineers set the air or lapped the brake and watched the leakage. When the train line drops 5 pounds, the brake handle is placed in running position a second or two and then placed back in lap position. This is repeated until the required speed is reached and brakes are released or a stop is made.

An example of using the feed valve was taking a train through Wabash. The depot and yard in Wabash sat along the Wabash River. The grade each way is around 2% and 2 1/2 to 2 3/4 miles to the top. My method was to put a piece of masking tape on the feed valve control for a mark, check the pressure on the equalizing gauge, place the throttle in #6 position and reduce equalizing pressure 5-7 pounds using the feed valve. As progress was made down the hill, brake pipe pressure was reduced in stages as speed was reduced. Total brake pipe reduction was usually 12-15 pounds and the throttle might have been reduced to 4th or 5th position. This would bring train speed down to 25-28 mph. The train line pressure was increased to the original pressure at 32-33 mph. By the time the brakes released the speed was at the 25-28 mph. This was done with 3 or 4 units and 125-135 cars ranging from 1 1/4 to 1 1/2 miles long and around 7000-8000 tons. Max speed at the time was 40 mph.

When northbound, I used the train air to control the train. You could use the partial release method and keep the train at 10 mph and release the brakes without stopping. This again was done with 100-130 cars. On a southbound trip, you could handle the train the same way and because the trains were, as a rule, of less tonnage it made it easier. A few of the engineers, including myself, when coming south and light on power, two EMD covered wagons with 100-120 cars, we would set the air at the normal location and ride the air to a point where the speed slowed to 30 mph. You then released the train air and applied the engine brakes with enough pressure to bunch the slack from front to back of the train before the brakes released on the train, but not so fast to cause slack action on the caboose. When this move was completed, the train was down to 12 to 15 mph. As you approached the bridge you could use one or two applications of the train air and proceed over the bridge at 10 mph again without stopping. There were other ways of braking and handling these trains, but the methods outlined here worked best for me. It was just as hard to pull trains out of Wabash but that is another story. Maurice Lewman

|

I have said this to show that freight trains can be and are handled safely with the air brakes. As with anything there are limits. As the brake valves on the engines and the AB's (control valves) on the cars improved you could apply the brakes and release them without stopping with 150-160 cars. In order to do this you must power brake. On diesels with this many cars, if you started in less than #6 throttle position you could be in a lot of trouble. This is what you were supposed to be learning while firing and taking turns with the engineers operating the train.

I have said this to show that freight trains can be and are handled safely with the air brakes. As with anything there are limits. As the brake valves on the engines and the AB's (control valves) on the cars improved you could apply the brakes and release them without stopping with 150-160 cars. In order to do this you must power brake. On diesels with this many cars, if you started in less than #6 throttle position you could be in a lot of trouble. This is what you were supposed to be learning while firing and taking turns with the engineers operating the train.

Another method was to use the feed valve. This worked well and I preferred to use it on the 5900-6000 series GP-9 with 24 RL brake valve when train line leakage was high. On the covered wagons such as General Motors, Alco or Fairbanks, the feed valve was on the back side of the brake stand and this made them hard to reach. Unless the train line was terrible, I used the lap and release method.

Another method was to use the feed valve. This worked well and I preferred to use it on the 5900-6000 series GP-9 with 24 RL brake valve when train line leakage was high. On the covered wagons such as General Motors, Alco or Fairbanks, the feed valve was on the back side of the brake stand and this made them hard to reach. Unless the train line was terrible, I used the lap and release method.

The bridge over the Wabash River was a curve from end to end. Due to lack of maintenance the speed was 10 mph on the bridge in later years. It was very difficult to never exceed the 10 mph over the bridge because it is uphill in both directions. If the power and train balanced out and the train air was good, you could come down the hill and across the bridge with the train air and maintain the 10 mph. Some engineers came to a stop at the bridge and started from there, but if the rear end runs in, it is very difficult to maintain the 10 mph limit.

The bridge over the Wabash River was a curve from end to end. Due to lack of maintenance the speed was 10 mph on the bridge in later years. It was very difficult to never exceed the 10 mph over the bridge because it is uphill in both directions. If the power and train balanced out and the train air was good, you could come down the hill and across the bridge with the train air and maintain the 10 mph. Some engineers came to a stop at the bridge and started from there, but if the rear end runs in, it is very difficult to maintain the 10 mph limit.